Air Compressors

All models are designed and manufactured locally in our Cambridge, Ontario facility. Many custom options available.

Lubricated Air Compressors

- Piston and screw types available

- Piston units up to 25 HP; assembled locally

- For industrial applications

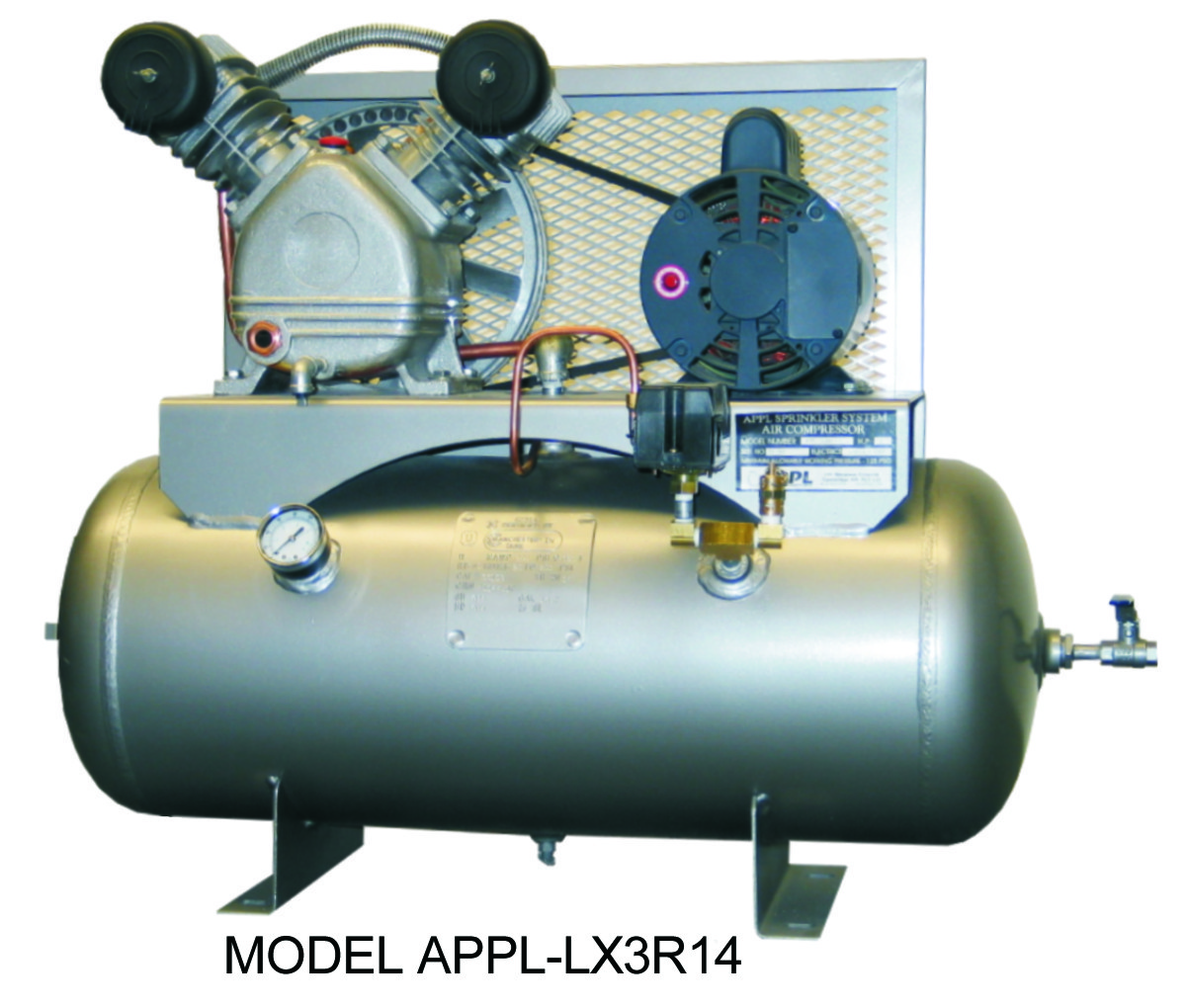

Sprinkler Air Compressors and Accessories

- Available from ½-10 HP

- Oil-free and lubricated types available

- Optional accessories available

Medical Air Compressors

- Z6396.1 compliant

- Oil-free, reciprocating or rotary scroll pumps offered

- Most replacement parts available from stock

- Custom packaged options for space limitations

- PLC based control systems with HMI high resolution touch screens

- Optional expandable systems for air demand increases